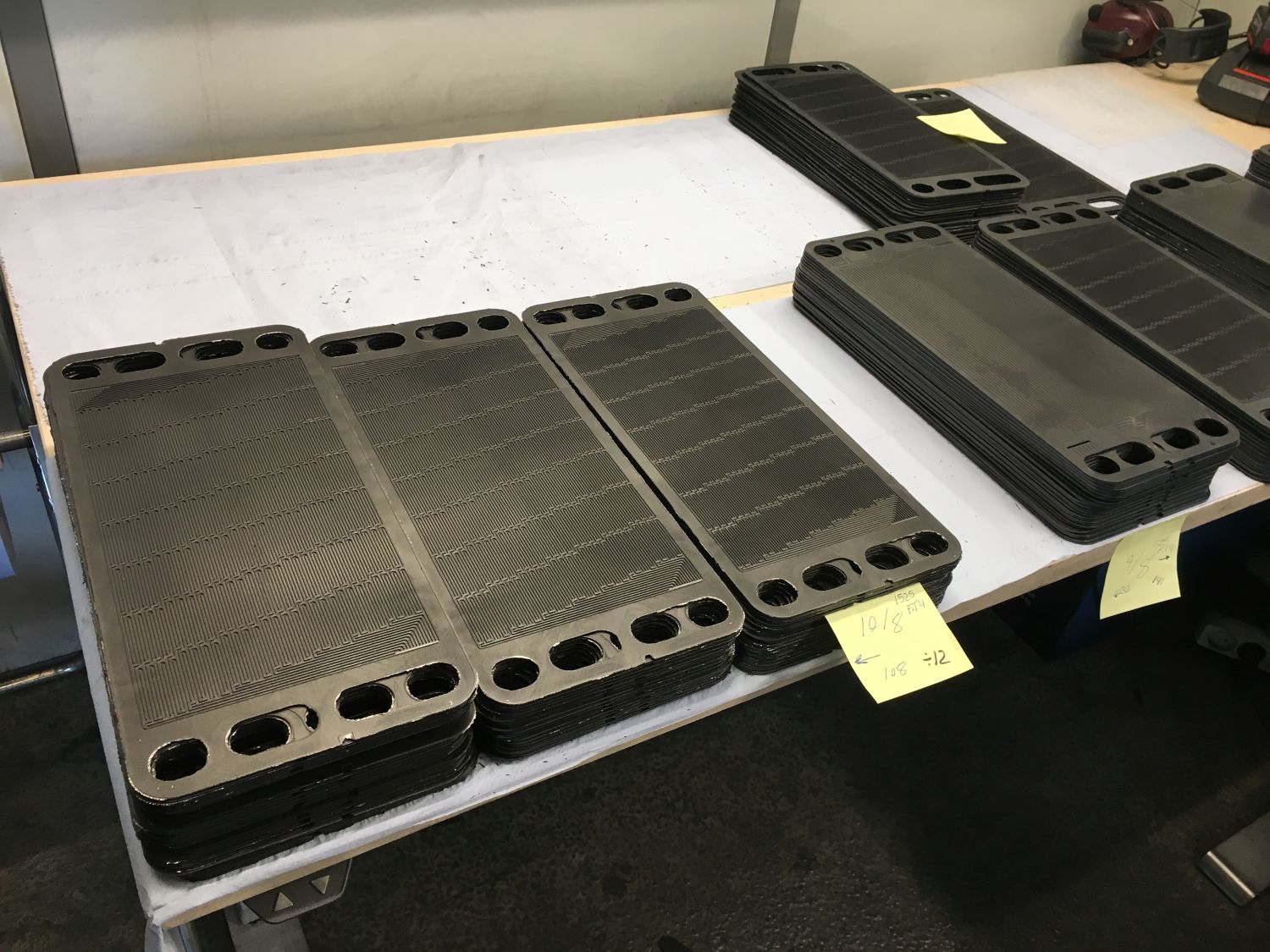

Fit-4-AMandA bipolar plates – the closed sealing design for automated stack assembly

A long process of iterative development of the graphitic BPPs (g-BPP) design to support the automated assembly process is now near completion. Most important is the design of a closed concept BPP in which the cathode and anode flowplates are supplied in a pre-sealed unit. Furthermore, alignment features were included to assist accurate plate positioning during stacking.

The resulting Fit-4-AMandA design represents the limit of what is possible with complex BPP geometries in terms of molding. It took its time, but the challenges have been resolved and the outcome is a state-of-the-art g-BPP. Manufacture of bipolar plates in the Fit-4-AMandA design is now at a stage where only trials to optimize the molding process followed by final validation is required before mass manufacture of g-BPPs can commence.

In parallel Fit-4-AMandA work on improving the conductivity of g-BPPs by removing the casting skin on the surface of the molded BPPs. Tentative results indicate that we can double the through-plane conductivity of post-processed g-BPPs compared to that of untreated g-PPs. (Metallic BPPs offer even higher conductivity, but they tend to corrode in the harsh conditions inside a PEM-FC). g-BPPs possess excellent corrosion resistance that enables long lifetimes, and Fit-4-AMandA demand a FC-design capable of 20,000+ hours of lifetime for the operation of supply vehicles that will be on the streets many hours daily. Effective removal of casting skin will further sustain that g-BPPs are the right choice for Fit-4-AMandA.