Development Blog

The aim of this blog is to give a step-by-step update about the progress done within the Fit-4-AMandA project. This is done by highlighting the most important milestones within the timeline of this project.

March 2017 – Kick Off Meeting

June 2017 – Specifications for the automatic machine ready!

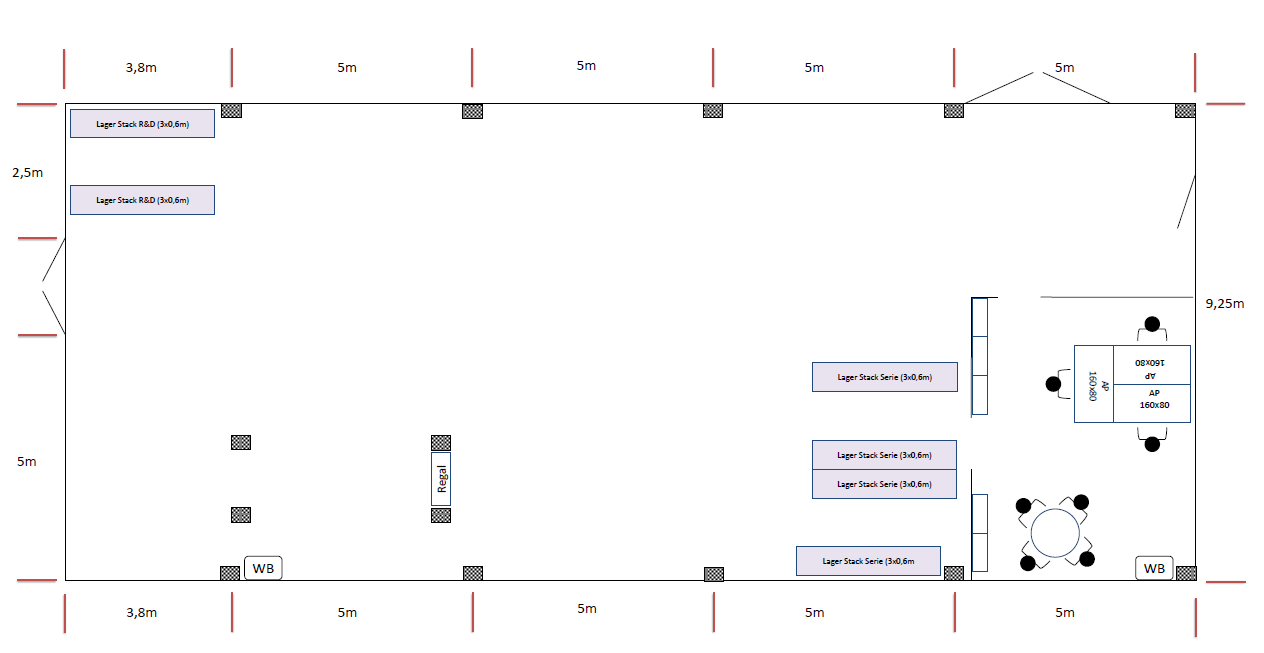

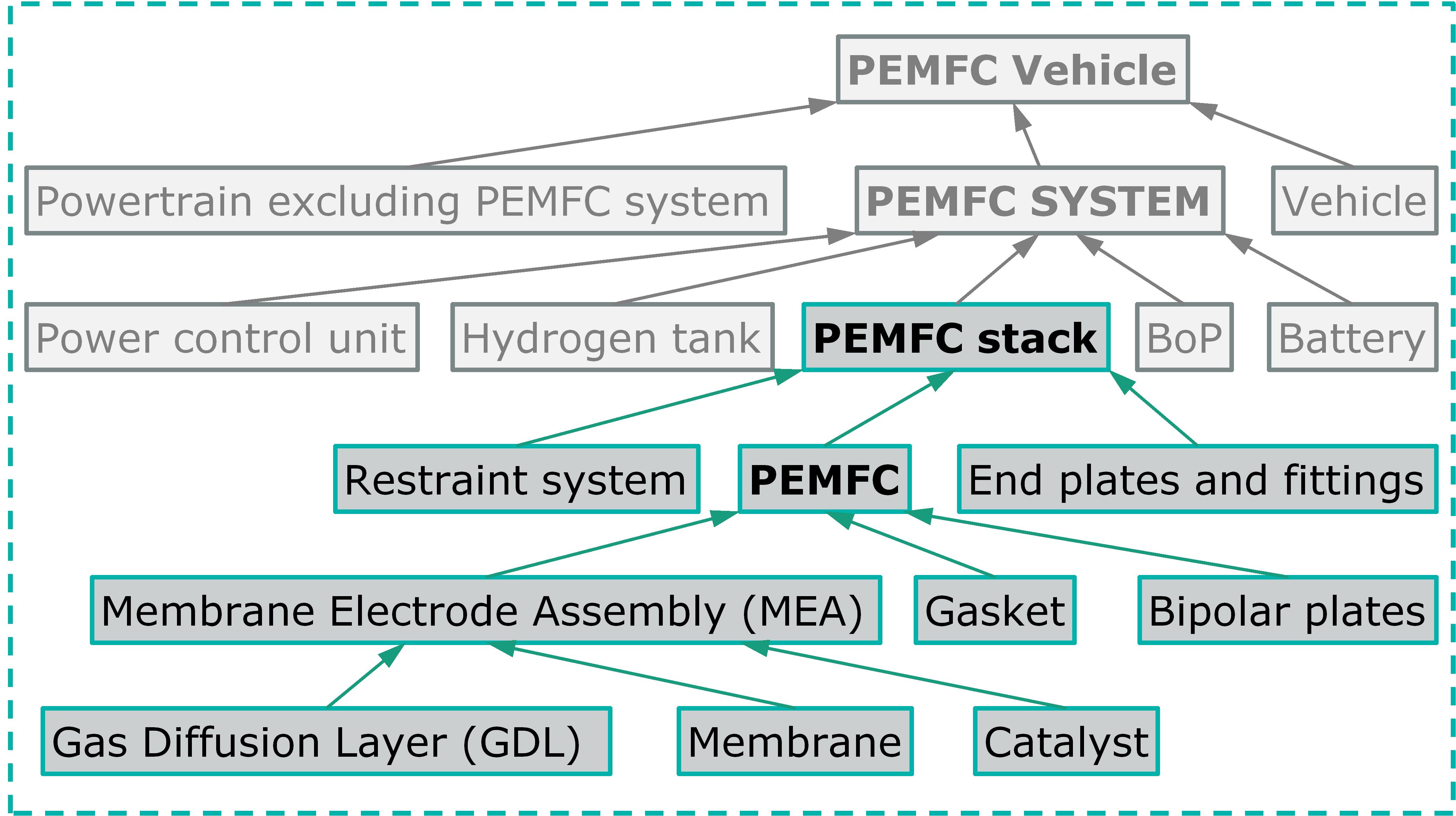

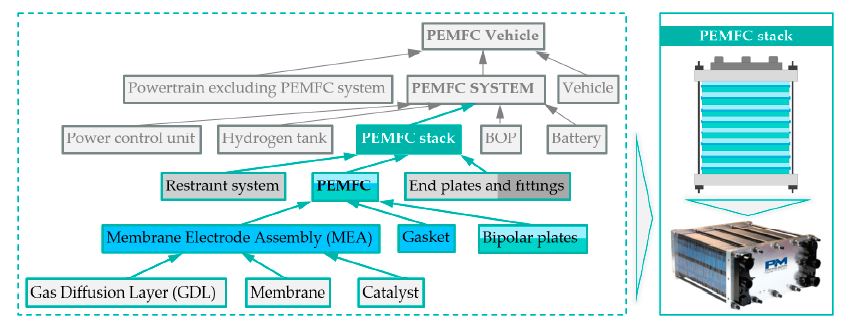

The formulation of the specifications of requirements for the automatic machine that will be producing stacks, which is the centrepiece of the fuel cell systems. Such requirements are the demands on the technology for the product manufacturing and also the product-side requirements for the processes of storage, supplying, assembling and handling. Read more in Deliverable 2.1…

August 2017 – Technology and business study complete

Complete a technology and business study in the field of fuel cell technologies in the transport sector (parcel delivery), depending on government requirements (latest pollution laws, etc.) and focusing on the production aspects of fuel cells. Read more in deliverable 1.1 and in deliverable 1.2

October 2017 – Specifications for the FC stack product ready!

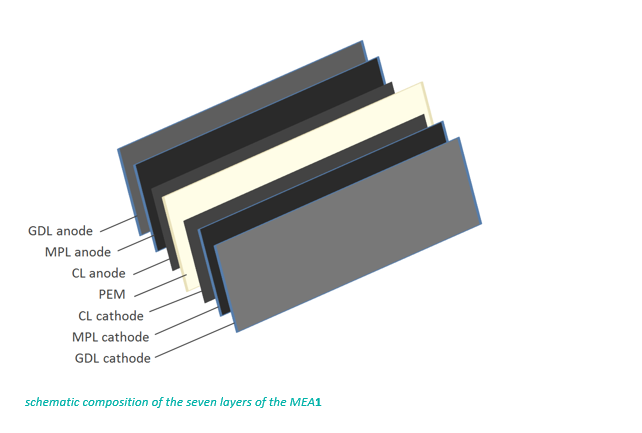

Specification related to the FC stack product, the machine design, the machine parameters and processing steps, as well as the quality control measures. Describing the concept – how and in what limits an automated PEMFC stack manufacturing plant could work and produce the targeted quality and quantity. Read more in deliverable 3.1…

January 2018 – Fuel cell stack design adapted

Parallel with development of assembly technology and equipment system – according the process requirements of automated manufacturing, assembly, transportation, handling, image processing and testing. Read more in deliverable 2.2…

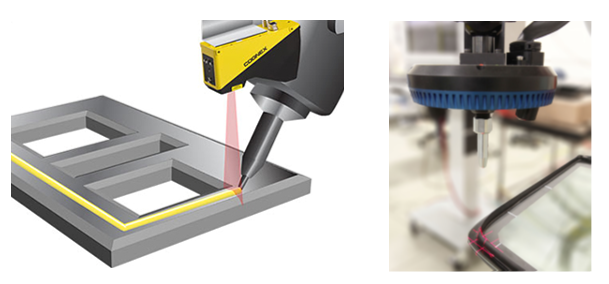

April 2018 – List of methods suitable for the fast in-line tests of fuel cell components and subassemblies are identified

The goal of this report is to provide a list of methods suitable for the fast in-line tests of fuel cell components and subassemblies. Read more in deliverable 5.1…

August 2018 – Feasibility study completed for FC technology in commercial EVs

The energy capacity of a high voltage battery was determined to cover, together with the produced PEMFC stack, the energy demands of the vehicle to travel the distance of 200 km. Influence of the driving cycle was studied and corresponding energy demands of the vehicle were calculated. To avoid focusing only on one tour (one type of driving cycle), a cycle based on average values of velocity and acceleration (from UPS’ standard package car route) was also used for computations. Read more in deliverable 6.1…

August 2018 – The experimental machine system is ready

The purchasing process is completed. The experimental machine system is assembled. The pneumatic and electrical installation is completed. The experimental machine system is now ready to start with mechanical tests of the functional units and to put it step by step into operation. Read more…

December 2018 – FC-Integration concept and performance requirements are ready

As part of the re-power offered by Proton Motor and EFA-S (responsible for the electric drive itself), an examination of the base vehicle (Mercedes Benz Vario P80E – 7.49T) is carried out by UPS. In Fit-4-Amanda the development for automated stack production will help to reduce costs which on the end helps the end user with a lower purchase prices and there for as well for market acceptance. With the integration of the FC stack into the base vehicle, the consortium aims to demonstrate the market readiness of such a mass manufactured product. The installation of the standard Electric drive (e-Motor, controller, charger etc.) will be accomplished by company EFA-S. EFA-S is a long term partner of UPS for conversion from diesel vehicles into BEV’s and are located in Zell u.A., Germany. The complete integration of the fuel system will be done by Proton Motor. Please see D6.2 and D6.3 for more information.

June 2019: Automatic mass manufacturing machine delivered to Proton Motor.

The automatic mass manufacturing machine has been delivered to Proton Motor. Read more…

October 2019: “Overcoming the Challenges for a Mass Manufacturing Machine for the Assembly of PEMFC Stacks”

Our Fit-4-AMandA colleagues have published the open access article: “Overcoming the Challenges for a Mass Manufacturing Machine for the Assembly of PEMFC Stacks” in the Journal ‘Machines’. Authors: Sebastian Porstmann (Fraunhofer IWU), Thomas Wannemacher (Proton Motor), Thilo Richter (Aumann).. Read more…